Proposal of parallel light illumination that is ideal for inspecting scratches on mirror surfaces and measuring dimensions such as screw diameters

1. Parallel light illumination that clearly captures the outline of the workpiece

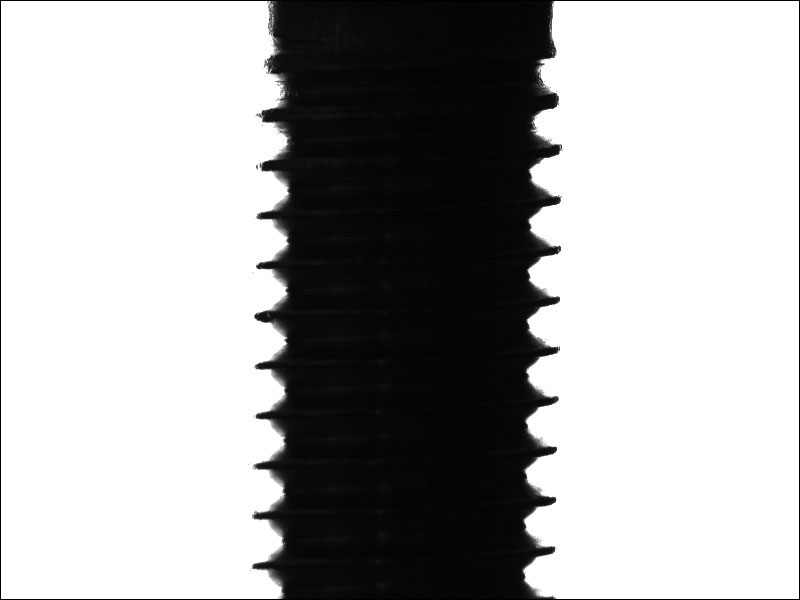

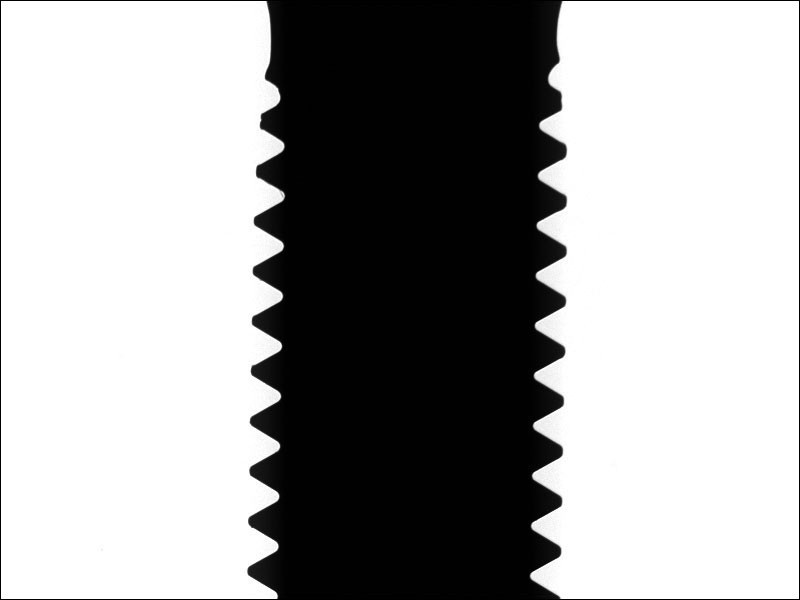

When measuring the outer diameter of a workpiece, if diffused lighting is used, the contour of the workpiece cannot be clearly captured due to light wraparound. If you need accurate dimensional measurement, please try parallel light illumination.

(blurred edges)

(sharp edges)

With a parallel light backlight, the outline of the workpiece can be clearly captured, and the workpiece (screw thread) can be accurately measured as shown in the image above. Also, with parallel light, errors due to workpiece position are less likely to occur than with diffuse backlights.

2. Also suitable for scratch inspection

As shown in the image below, the parallel light backlight is ideal for inspecting scratches on specular objects such as glass substrates and mirrors that reflect specularly.

(Unable to detect specular reflection scratches)

(Scratches of specular reflection can be detected)

Opto Engineering's "LTCLHP CORE SERIES Telecentric Ultra Compact Design Large Aperture LED Illuminator", which we handle, has a compact design compared to other companies' parallel light illumination, which leads to a reduction in inspection space.